Pompes pneumatiques A membranes

AIR OPERATED DOUBLE DIAPHRAGM PUMPS

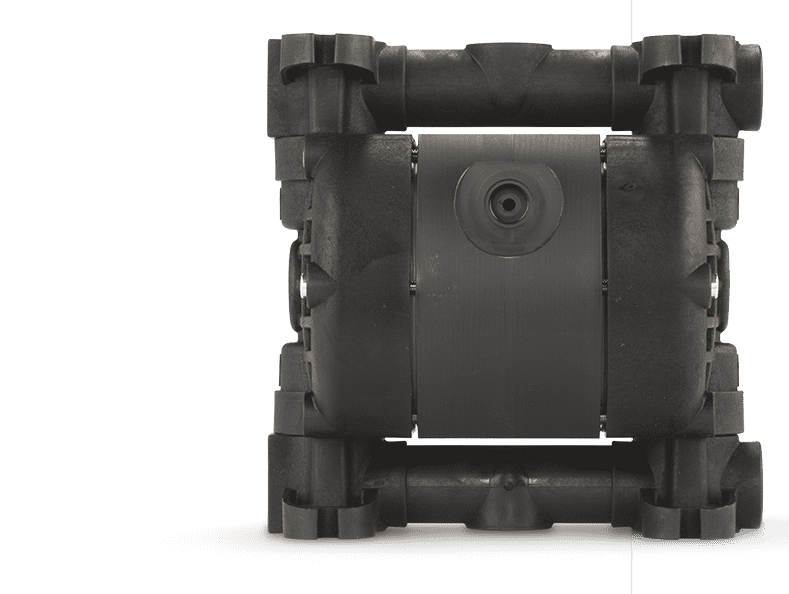

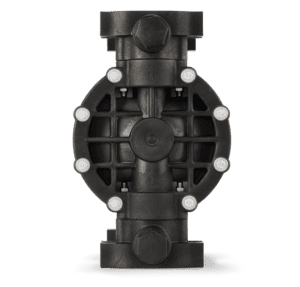

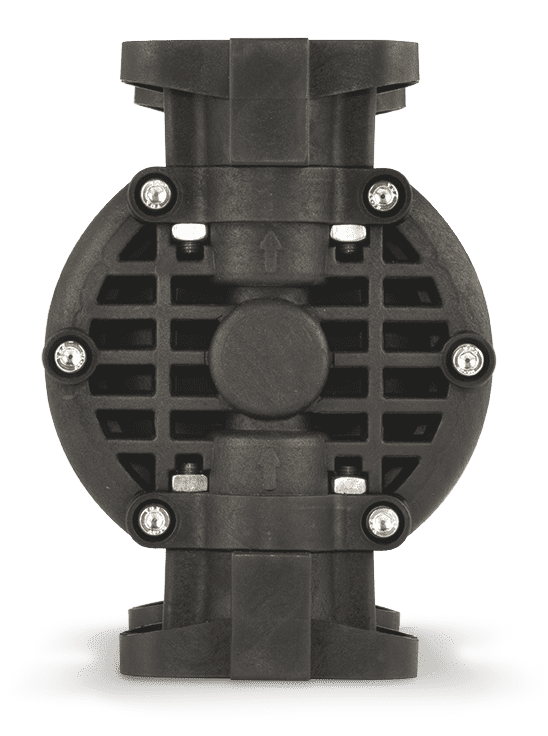

BX SERIES: PLASTIC PUMPS

Double diaphragm pumps made of thermoplastic (PP, PVDF, ECTFE). Suitable for the movement of corrosive chemicals, viscous fluids and dense liquids. Maximum flow rate: 800 l/min. Maximum head: 8 bar.

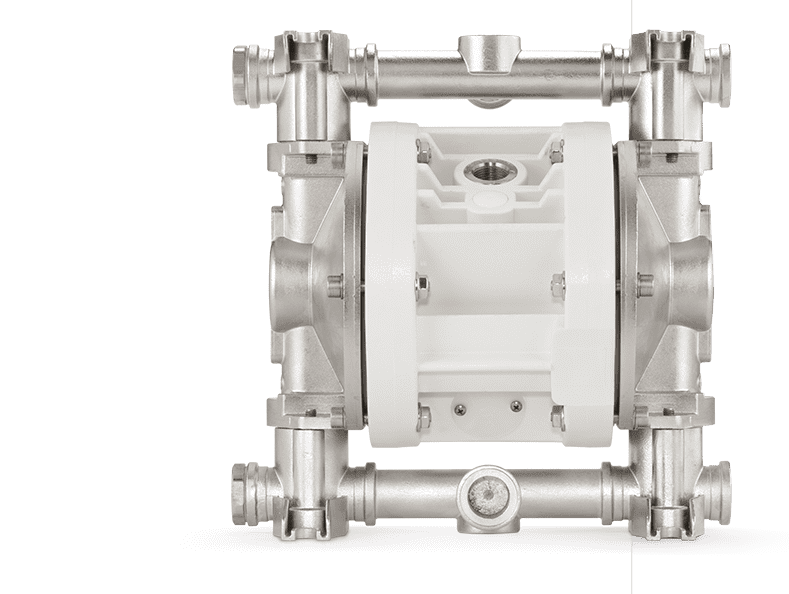

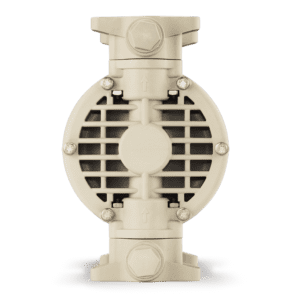

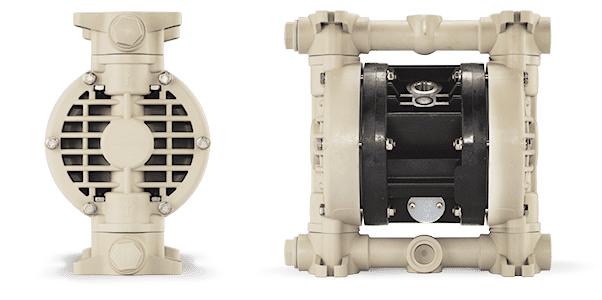

BX SERIES: METAL PUMPS

Double diaphragm pumps made of metal (steel, aluminium). Compatible fluids: non-aggressive industrial liquids, flammable liquids, dense fluids and viscous products (oils). Maximum flow rate: 800 l/min. Maximum head: 8 bar.

BX SERIES: PLASTIC PUMPS

Double diaphragm pumps made of thermoplastic (PP, PVDF, ECTFE). Suitable for the movement of corrosive chemicals, viscous fluids and dense liquids. Maximum flow rate: 800 l/min. Maximum head: 8 bar.

BX SERIES: METAL PUMPS

Double diaphragm pumps made of metal (steel, aluminium). Compatible fluids: non-aggressive industrial liquids, flammable liquids, dense fluids and viscous products (oils). Maximum flow rate: 800 l/min. Maximum head: 8 bar.

INTERNAL DIAPHRAGMS

There are two pairs of diaphragms inside the BX pneumatic pumps and these are obviously the elements subject to the greatest stress during suction and pumping (both at chemical and mechanical level). The membranes are designed to redistribute the load, minimising the yielding of the material. The possible anti-acid and wear-resistant configurations are: plastic (Hytrel, Santoprene), rubber (NBR, EPDM) or PTFE.

THERMOPLASTIC MATERIALS

PP (POLYPROPYLENE)

The most widely used thermoplastic polymer for the construction of anti-acid centrifugal pumps. It offers good resistance to most acid and alkaline solutions and can be used, depending on the concentration of the aggressive liquids, at temperatures of up to 80°C.

PVC (POLYVINYL CHLORIDE)

METAL (AISI316L AND ALUMINIUM)

HOW THEY WORK

SOME CORROSIVE LIQUIDS

- Nitric acid

- Muriatic acid

- Citric acid

- Brine, Ammonia

- Caustic potash

- Chemical fertilisers

- Fertilisers

- Glycerine, glycol

- Fuels and biodiesel

- Various solvents

- Seawater

- Sulphuric acid

- Caustic soda

- Hydrochloric acid

- Sodium hydroxide

- Chromic acid

- Sodium hypochlorite

- Hydrofluoric acid

- Ferric chloride

- Aluminium polychloride

- Phosphoric acid

- Acetic Acid

- Flocculants

- Polyelectrolytes

- Urea and AdBlue

- Sanitising gels

- Inks, dyes, paints

- Vegetable oils

- Industrial oils

- Cosmetic liquids

- Industrial detergents

- Distilled water

- Demineralised water

- Hydrogen Peroxide

- And your liquid of course!

- Nitric acid

- Muriatic acid

- Citric acid

- Brine, Ammonia

- Caustic potash

- Chemical fertilisers

- Fertilisers

- Glycerine, glycol

- Fuels and biodiesel

- Various solvents

- Seawater

- Sulphuric acid

- Caustic soda

- Hydrochloric acid

- Sodium hydroxide

- Chromic acid

- Sodium hypochlorite

- Hydrofluoric acid

- Ferric chloride

- Aluminium polychloride

- Phosphoric acid

- Acetic Acid

- Flocculants

- Polyelectrolytes

- Urea and AdBlue

- Sanitising gels

- Inks, dyes, paints

- Vegetable oils

- Industrial oils

- Cosmetic liquids

- Industrial detergents

- Distilled water

- Demineralised water

- Hydrogen Peroxide

- And your liquid of course!

OTHER FEATURES

- Compact design, ideal for reduced industrial spaces.

- Suitable for dry running.

- Volumetric pumps characterised by pulsating flow rate.

- Suitable for use in explosive environments (Atex Certification).