POMPE E AGITATORI

RESISTENTI ALLA CORROSIONE

POMPARE E MISCELARE

Se dovete pompare liquidi aggressivi, distribuire prodotti chimici, miscelare acque industriali, travasare acidi pericolosi, movimentare soluzioni corrosive, allora le nostre pompe e i nostri agitatori solo la risposta giusta alle vostre esigenze: sono infatti totalmente resistenti alla corrosione.

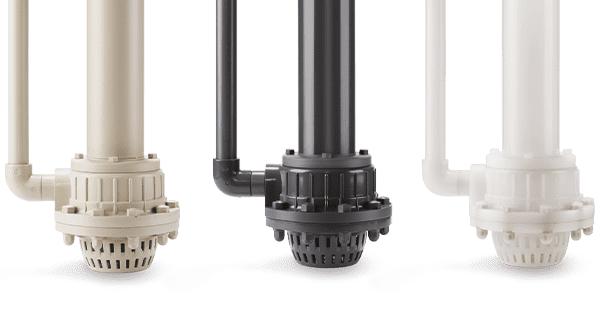

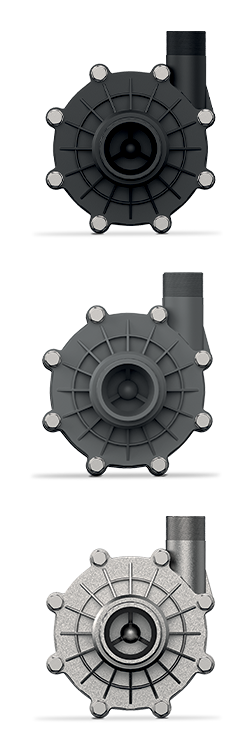

POMPE CHIMICHE VERTICALI

Pompe centrifughe verticali per acque industriali e liquidi corrosivi anche lievemente carichi. Le pompe chimiche verticali Savino Barbera, grazie alla loro costruzione senza misure standard si adattano a qualsiasi profondità (da 200 a 3000 mm). Portata massima: 200 m³/h. Prevalenza massima: 55 m w.c.

Realizzate in materiali plastici resistenti alla corrosione: PP, PVC, PVDF.

COSTRUZIONE PLASTICA

Pompe e agitatori Savino Barbera sono costruiti in materiali termoplastici anti-corrosione (PP, PVC, PVDF). In particolare, le nostre macchine sono integralmente realizzate in plastica anti-acido mentre i pochi necessari componenti metallici esistenti sono protetti da rivestimenti in polimeri tecnici. Il risultato è che non ci sono parti metalliche a contatto diretto con i liquidi aggressivi. Meno metallo, meno corrosione, meno problemi.

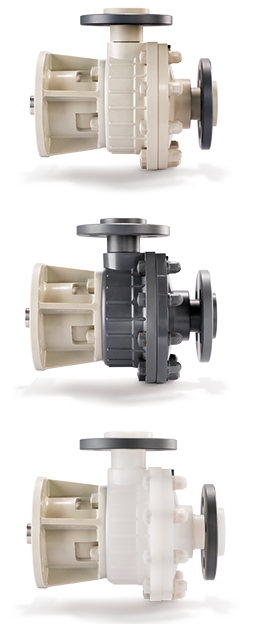

POMPE CHIMICHE ORIZZONTALI

Pompe centrifughe orizzontali per il pompaggio di acidi e liquidi aggressivi. Le pompe chimiche orizzontali Savino Barbera, sono caratterizzate da un design monoblocco e dalla presenza di una tenuta meccanica anti-acido adatta ad applicazioni chimiche. Portata massima: 200 m³/h. Prevalenza massima: 55 m w.c. Realizzate in materiali plastici anti corrosione: PP, PVC, PVDF.

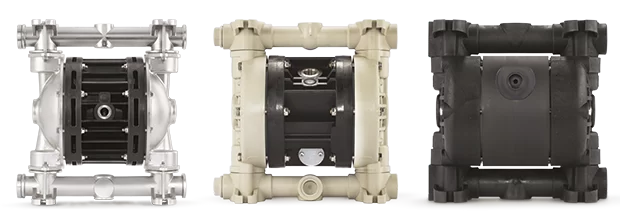

design MODULARE

Il concetto modulare dei nostri prodotti su misura ci consente di fornire macchinari adatti ad innumerevoli impianti o ad applicazioni fuori standard. Le attrezzature in plastica Savino Barbera sono infatti disponibili in varianti costruttive diversificate in modo da poter essere installate nei più diversi processi industriali.

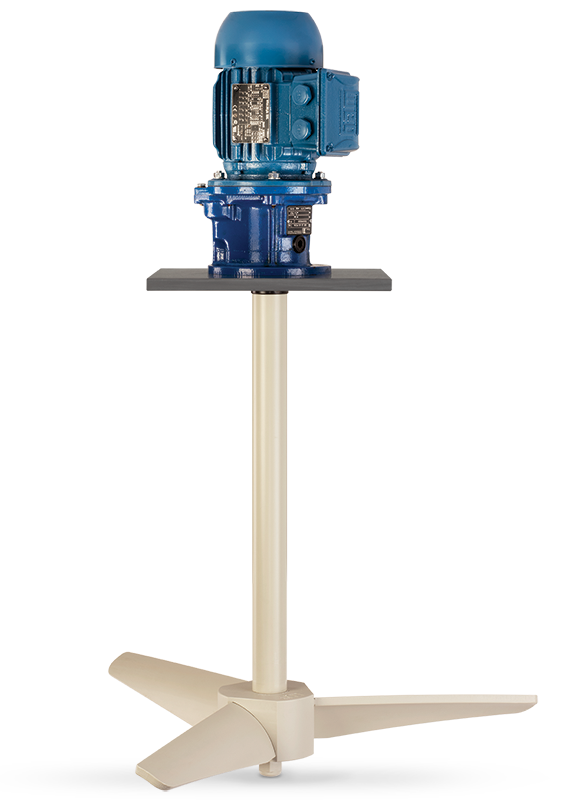

agitatori industriali

Agitatori fissi flangiati, a presa diretta o accoppiati a motoriduttori. Per installazioni in serbatoi a pressione atmosferica. Ad alta, media, bassa velocità. Realizzati su misura fino a lunghezze massime di 3500 mm, possono montare motori da 4, 6 e 8 poli. Con giranti marine, turbine assiali a pale inclinate, giranti metalliche richiudibili, giranti ad alta efficienza. Materiali plastici anti-corrosione (PP, PVC, PVDF) e metallo.

MANUTENZIONE SEMPLIFICATA

Le pompe e gli agitatori Savino Barbera sono realizzati in plastica anti-corrosione e sono composti da pochi essenziali elementi che possono essere agevolmente smontati e riparati. I pezzi di ricambio sono sempre disponibili anche ad anni di distanza dalla fornitura originale. Inoltre, la loro manutenzione normalmente non richiede competenze o abilità particolari.

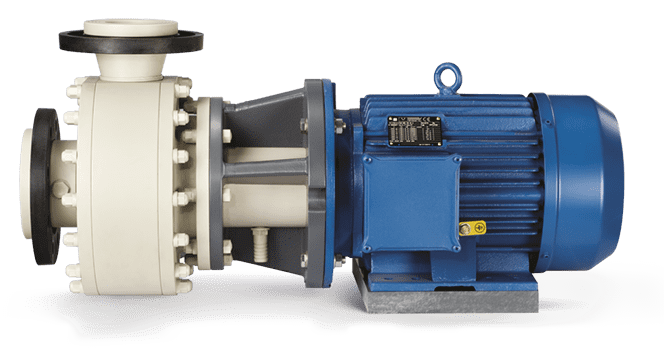

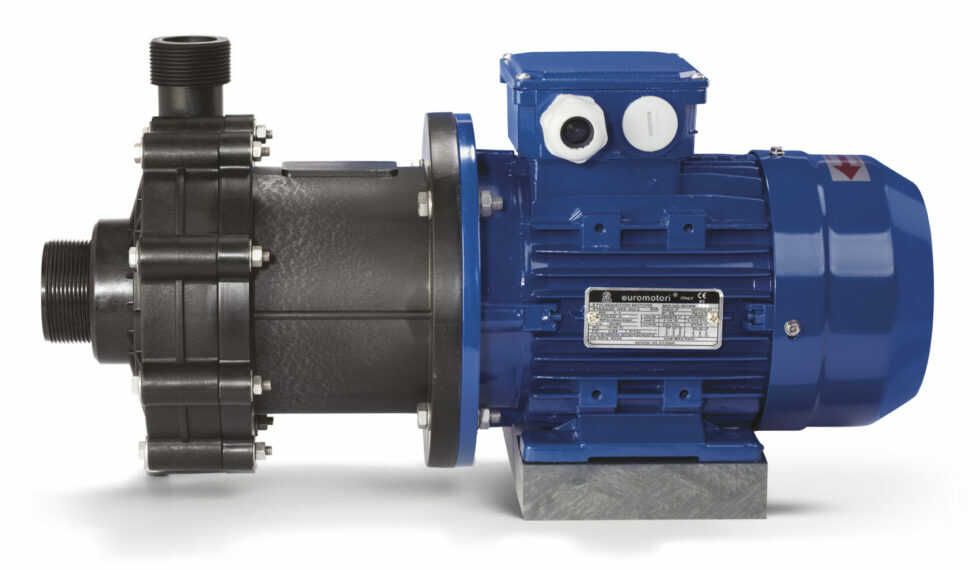

pompe magnetiche

Pompe a trascinamento magnetico per acidi corrosivi, tossici o pericolosi, usati nel settore chimico, petrolchimico e farmaceutico. Le pompe magnetiche BM sono adatte solo a liquidi aggressivi privi di solidi (soprattutto metallici). Le pompe con giunto magnetico sono disponibili in plastica anti-corrosione (PP e PVDF) e metallo (AISI 316, HASTELLOY). Portata massima: 135 m³/h. Prevalenza massima: 48 m w.c.

LA SCELTA GIUSTA

I materiali costruttivi dei nostri prodotti sono rigorosamente selezionati in funzione del fluido corrosivo trattato. Per scegliere il corretto modello di pompa o agitatore anti-corrosione è quindi sempre consigliabile affidarsi alla competenza di chi questa selezione è abituato a farla da anni: la nostra esperienza rimane un valore aggiunto decisivo, soprattutto quando si movimentano liquidi critici.

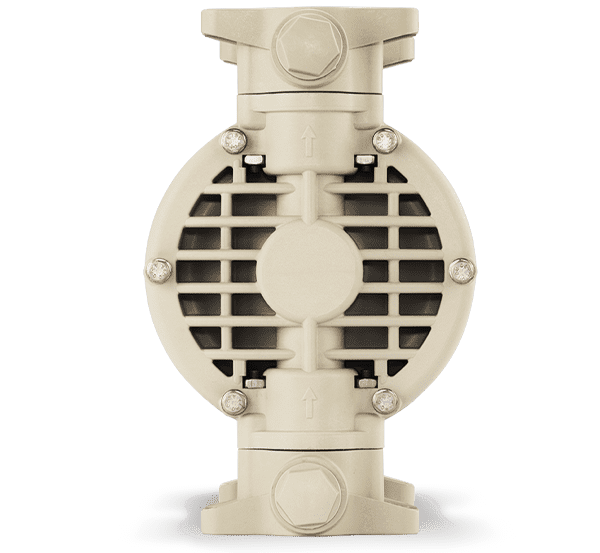

pompe a membrana

Pompe pneumatiche a doppia membrana. Per liquidi viscosi, fluidi abrasivi o infiammabili, oli, vernici, inchiostri, carburanti, fluidi alimentari e farmaceutici. Prodotte in materiale plastico (PP, ECTFE, PVDF) e metallo (acciaio inox e alluminio). Portata massima: 800 l/min. Prevalenza massima: 8 bar.

LIQUIDI CORROSIVI

Pompe e agitatori Savino Barbera sono compatibili con innumerevoli sostanze chimiche corrosive. Qualche esempio: acido solforico, cloruro ferrico, acido cloridrico, idrossido di sodio (soda caustica), acido cromico, ipoclorito di sodio, acqua di mare, acido fosforico, salamoia, acido nitrico, ammoniaca, perossido di idrogeno, carburanti, AdBlue, urea, acido fluoridrico, detergenti, solventi, fertilizzanti… E il vostro liquido, naturalmente!

Altri prodotti

Oltre alle sue tradizionali pompe plastiche resistenti alla corrosione, Savino Barbera produce anche ulteriori manufatti per liquidi chimici, utilizzabili per le svariate esigenze degli impianti industriali: pompe per fusti e barili, pompe disincrostanti per lavaggi chimici e bulloneria rivestita in plastica per ambienti aggressivi in genere.

HAI UNA RICHIESTA ?

PARLA CON UN TECNICO